How is the size of the fixed baffle of the car trunk determined? How to ensure that the fixed baffle fits perfectly with the trunk of various models to achieve the best fixing effect?

1. Determination of the size of the fixed baffle of the car trunk

Understand the model and needs:

Before determining the size of the fixed baffle, you need to first clarify the model and the specific structure of the trunk. The size, shape and internal structure of the trunk of different models vary greatly, so it must be customized according to the model.

At the same time, the needs of the owner are also an important factor to consider. For example, the type and quantity of stored items and whether additional functions (such as waterproofing and sound insulation) are required, which will affect the design size and material selection of the baffle.

Accurately measure the size of the trunk:

In order to ensure the suitability of the baffle, the owner or professional measurement personnel need to accurately measure the size of the trunk, including length, width and height. The shape and structure of the trunk should be considered during measurement to ensure the accuracy of the data.

In addition, the bulges, depressions or special structures that may exist inside the trunk should also be considered so that they can be avoided or adapted when designing the baffle.

Design and custom production:

After obtaining accurate measurement data, you can start designing the baffle plan. This step is usually completed by professional auto parts manufacturers or designers.

When designing the plan, you should combine the model, owner's needs and measurement data to ensure that the baffle can fit tightly to the edge of the trunk after installation to achieve the best fixing effect.

After completing the design plan, you can proceed with custom production. During the production process, the material, process and quality should be strictly controlled to ensure that the baffle meets the design requirements.

Second, ensure that the fixed baffle fits perfectly with the trunk of various models

Personalized customization:

As mentioned earlier, the trunk size and structure of different models vary greatly, so the fixed baffle must be customized according to the model.

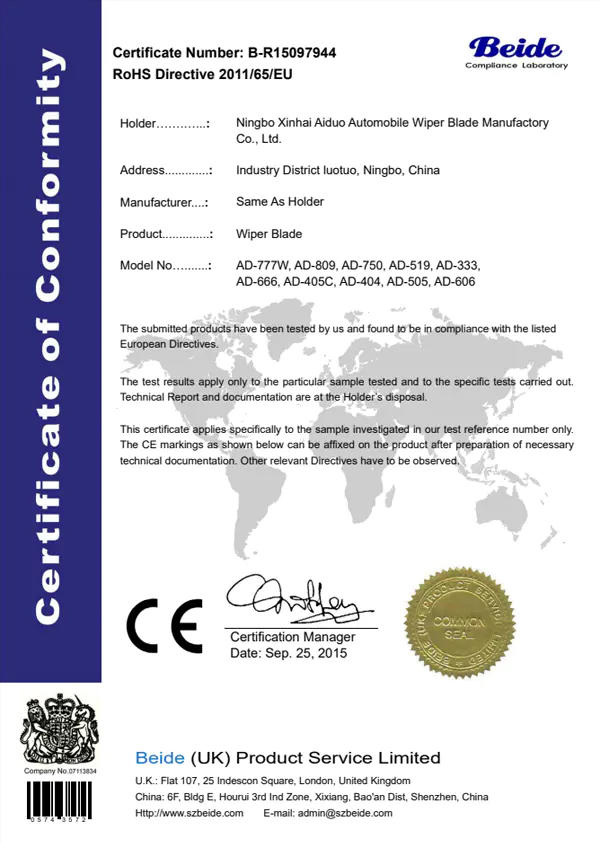

Aido Wiper Company has an independent design and development team that can perform personalized design according to customer needs. This design concept is also applicable to the production and manufacturing of fixed baffles. Through personalized customization, the baffle can be perfectly matched with the trunk of the model.

Use modern design concepts:

When designing wiper blades, Aido Wiper Company uses modern mechanics, aeronautics, acoustics, optics and other personalized design concepts. These design concepts can also be applied to the design of fixed baffles.

For example, by applying the principles of mechanics, the structural design of the baffle can be optimized to improve its bearing capacity and stability; by applying the principles of acoustics, the noise generated by the baffle during driving can be reduced; by applying the principles of optics, the aesthetics and visual effects of the baffle can be improved.

Strict quality control:

In order to ensure the quality of the fixed baffle, every link in the production process should be strictly controlled. From raw material procurement, production and processing to finished product inspection, strict quality standards and control processes should be followed. This quality control concept also applies to the production and manufacturing of fixed baffles. Through strict quality control, it can be ensured that the baffle can be used stably for a long time after installation.

Professional installation and debugging:

The installation process of the fixed baffle is equally important. Before installation, it should be ensured that the selected baffle is fully matched with the vehicle model, and the necessary installation tools and materials should be prepared.

During the installation process, the installation instructions should be strictly followed to ensure that the installation position of the baffle is accurate and firmly fixed. After the installation is completed, debugging and inspection should also be carried out to ensure that the baffle will not loosen or produce abnormal noise during use.

Regular maintenance and inspection:

In order to ensure the long-term stability of the fixed baffle, the owner should perform regular maintenance and inspection. The inspection content includes the fixing condition of the baffle, the degree of wear, and whether it is deformed or damaged.

If the baffle is found to be loose or damaged, it should be tightened or replaced in time. Through regular maintenance and inspection, the service life of the baffle can be extended and its good fixing effect can be ensured at all times.

English

English  中文简体

中文简体