How to ensure the precision and quality control of metal wipers during processing to reduce the scrap rate?

Strategies to ensure the precision and quality control of metal wiper processing

As a key component of automobiles, the quality and precision of metal wipers are directly related to driving safety and user experience. During the production and processing process, ensuring the precision and quality control of metal wipers to reduce the scrap rate is an important issue facing manufacturing companies. The following is a comprehensive set of strategies to optimize the processing process, improve product quality, and reduce the scrap rate.

1. Optimize process flow and upgrade equipment

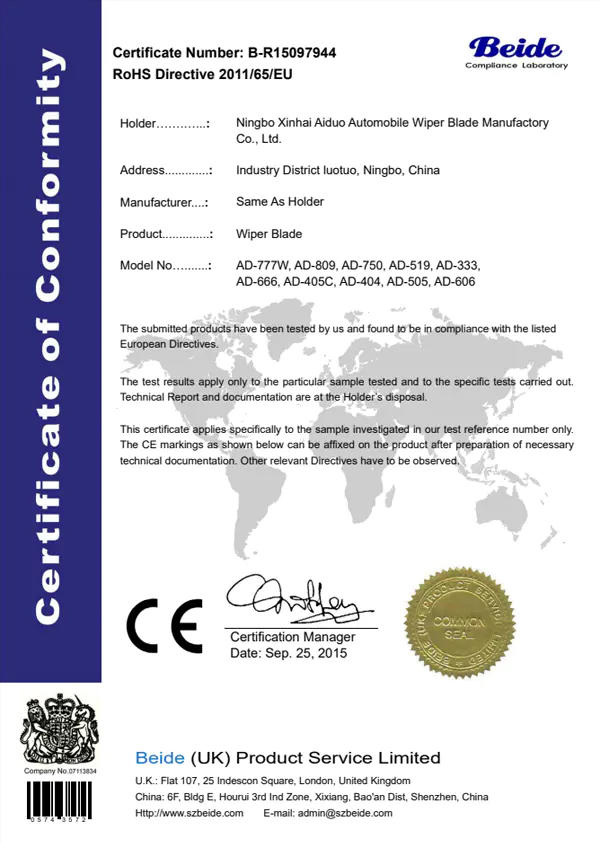

Optimizing the process flow is the basis for ensuring the precision of metal wiper processing. Through in-depth analysis and evaluation of the existing process flow, potential sources of errors and scrap generation links are identified, and targeted improvement measures are taken. For example, the introduction of advanced cutting technology and high-precision processing equipment, such as CNC machine tools, can significantly improve processing accuracy and efficiency. Ningbo Xinhai Aido Automobile Wiper Blade Manu. Co., Ltd. uses the world's advanced cutting technology to ensure the high precision of wipers during processing.

In addition, equipment upgrade is also an important means to improve processing accuracy. Regularly maintain and inspect the processing equipment to ensure that it is in the best working condition and avoid the generation of waste products due to equipment failure. At the same time, choosing processing equipment with stable performance and high precision, such as high-precision grinders, CNC machine tools, etc., can further reduce processing errors and improve product quality.

2. Strict raw material quality control

The quality of raw materials directly affects the precision and quality of the final product. Therefore, in the processing of metal wipers, the quality of raw materials must be strictly controlled. Select high-quality and stable raw material suppliers to ensure that the physical properties, chemical properties and dimensional accuracy of the raw materials meet the processing requirements. Before the raw materials are put into storage, strict inspection and testing are carried out to eliminate unqualified products and ensure that each batch of raw materials meets the production standards.

3. Implement strict quality inspection and monitoring

Quality inspection and monitoring are the key links to ensure the processing accuracy and quality of metal wipers. During the processing process, multiple quality inspection points are set up to strictly inspect and monitor each processing link. Use advanced testing equipment and tools, such as micrometers, height gauges, vernier calipers, etc., to accurately measure and evaluate the dimensional accuracy and surface quality of the products. Once unqualified products are found, they are immediately traced and isolated to prevent them from entering the next process or flowing into the market.

In addition, establishing a sound quality management system is also an important means to improve product quality and reduce scrap rate. By introducing ISO quality management standards or other relevant certifications, standardize the production process and product quality control process to ensure that every production link meets the quality standard requirements.

4. Continuous improvement and innovation

Continuous improvement and innovation are the eternal themes to ensure the processing accuracy and quality control of metal wipers. By continuously optimizing process flow, upgrading equipment, strengthening raw material quality control, improving employee skills, and implementing strict quality inspection and monitoring, we can continuously improve product quality and processing accuracy. At the same time, we actively introduce new technologies, new processes and new materials to promote continuous innovation and upgrading of products to meet the ever-changing needs of the market and customers.

English

English  中文简体

中文简体