How to choose the right natural rubber raw material to ensure the wiping effect and durability of natural rubber wiper blades?

Choosing the right natural rubber raw material is crucial to ensure the wiping effect and durability of natural rubber wiper blades. As one of the key components of a car, the performance of the wiper blade directly affects the driver's visual clarity and driving safety. Therefore, during the manufacturing process, the selection of raw materials must be strictly considered to meet the requirements of efficient wiping and long-term durability.

Principles for selecting natural rubber raw materials

1. Purity and freshness

The purity of natural rubber is an important indicator of its quality. High-purity natural rubber contains fewer impurities and can provide better elasticity and wear resistance, which is crucial for the performance of wiper blades in adverse weather conditions. In addition, the freshness of the raw materials cannot be ignored. Fresh natural rubber has better processing performance and vulcanization effect, which can ensure that the wiper blades achieve optimal performance during the manufacturing process.

2. Physical properties

The physical properties of natural rubber, such as tensile strength, tear strength and hardness, directly affect the durability and wiping effect of wiper blades. High tensile strength and tear strength mean that wiper blades can better resist deformation and breakage, extending their service life. Appropriate hardness ensures a tight fit between the wiper blade and the windshield, improving wiping efficiency.

3. Weather resistance

Wiper blades need to withstand a variety of climatic conditions, including high and low temperatures, humidity and UV exposure. Therefore, it is crucial to select natural rubber raw materials with excellent weather resistance. Such raw materials can effectively resist aging, maintain the elasticity and wiping performance of wiper blades, and work stably even in extreme environments.

4. Chemical resistance

Chemical substances on the road, such as oil stains, salt water and road cleaners, can cause damage to wiper blades. Therefore, the selected natural rubber raw materials should have good chemical resistance to prevent these substances from corroding the wiper blades and affecting their wiping effect and life.

Raw material screening and testing

In order to ensure that the selected natural rubber raw materials meet the above requirements, manufacturers should conduct rigorous screening and testing. This includes chemical composition analysis of the raw materials, physical property testing, and durability testing that simulates actual usage conditions. Through these tests, the performance of the raw materials can be accurately evaluated and the most suitable raw materials for manufacturing high-quality wiper blades can be screened out.

Quality control during production

After selecting the appropriate natural rubber raw materials, quality control during production is equally important. Ningbo Xinhai Aido Automobile Wiper Blade Manu. Co., Ltd. has internationally advanced automated production and testing equipment, which provides a strong guarantee for ensuring the quality of wiper blades. The performance of wiper blades can be further optimized by precisely controlling production process parameters such as temperature, pressure and vulcanization time. At the same time, advanced testing equipment can monitor product quality in real time, detect and solve potential problems in a timely manner, and ensure that each wiper blade meets high standards.

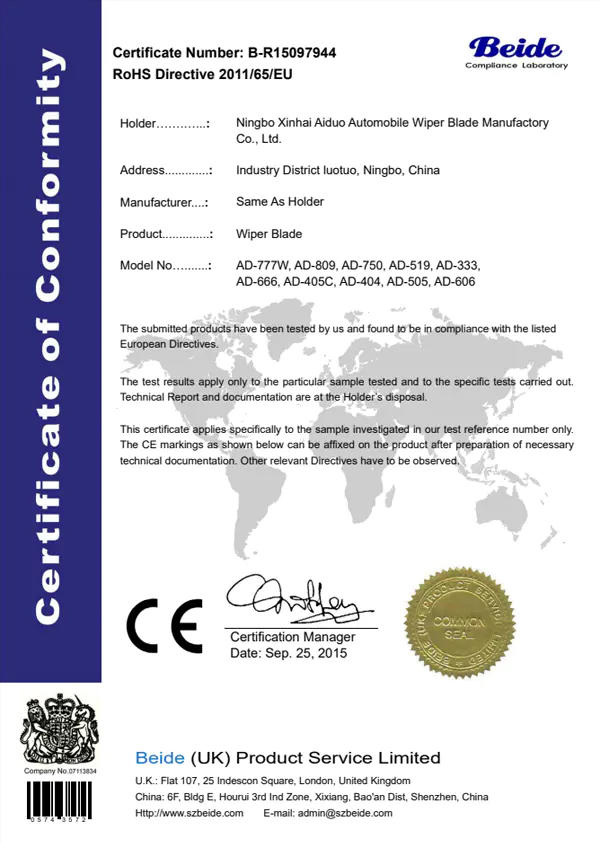

Selecting the right natural rubber raw materials is the basis for ensuring the wiping effect and durability of wiper blades. Through strict selection of raw materials, performance testing, and implementation of high-quality production control, Ningbo Xinhai Aido Automobile Wiper Blade Manu. Co., Ltd. is committed to providing customers with wiper blade products with excellent performance, durability and reliability. As a quality company certified by ISO9001:2000 and ISO/TS 16949, we always put product quality first, and continuously innovate and optimize production processes to meet the market demand for high-quality wiper blades.

English

English  中文简体

中文简体